Hello from FedInvent,

On Tuesday, January 25, 2022, USPTO granted 5,744 new patents. One hundred thirteen (113) benefited from taxpayer funding.

Here are the links to this week's FedInvent Patent Report. If you prefer to browse by federal department, start here.

Last week we added year-to-date funding citation totals for patent and application counts by department. This week we added year-to-date funding citation counts for the Health Complex — HHS, NIH, and the Institutes. The Health Complex is a taxpayer-funded intellectual property machine. We are four weeks into 2022, and HHS and its parts have been cited as the funding source 166 times.

3D Printing Buildings and Knuckles

Additive manufacturing, also known as 3D printing or additive fabrication, enables the manufacture of things — jet engine parts, custom skull plates, fissile fuel blocks for nuclear energy, prosthetic fingers, and buildings. Computer-aided designs drive print heads that spray-on materials layer by layer. The process works much the same way as an inkjet printer. If you can spray ink on paper, why can you spray metal alloys on top of each other to make jet parts?

Additive manufacturing and materials needed to make 3D printing work are among the top ten R&D science and technology priorities to maintain US global innovation leadership. The global 3D printing market is expected to grow from USD 12.6 billion in 2021 to USD 34.8 billion by 2026, at a CAGR of 22.5%. The US wants its piece of the action and is funding the R&D to make sure it gets it. In 2021, taxpayer-funded R&D resulted in 40 new patents.

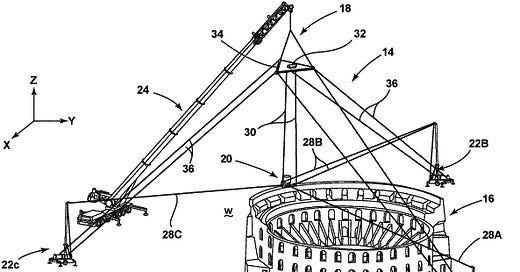

The building technologies and manufacturing researchers at Oak Ridge National Laboratory (ORNL) decided to go big. On Tuesday, UT-Battelle, the LLC that holds the contract to operate the Lab for the Department of Energy, received US Patent 11230032, "Cable-driven additive manufacturing system." The technology is for building concrete buildings layer-by-layer using 3D printing.

ORNL's Sky Big Area Additive Manufacturing (SkyBAAM) program created is a cable-driven motion platform designed for fieldable additive manufacturing (AM) at construction scale. Technically their invention is for cementitious 3D construction printing (3DCP) or 3D concrete printing. 3D concrete printing is a form of additive manufacturing used to fabricate buildings or construction components in entirely new shapes not previously possible with traditional concrete formwork. A concrete form or formwork is a scaffolding or mold into which the concrete is poured at construction sites.

ORNL's design uses pumpable concrete that is dispensed in layers. 3D cement can be made of mixtures that involve cement, fibers, and other ingredients mixed in with water. Other materials include castable clay, mortar, synthetic polymers, and old plastic (recycled). To advance fieldable, construction scale 3D printed buildings, ORNL has signed a Cooperative Research and Development Agreement with Quikrete to design next-generation concrete for use in the production of large-scale structures through 3D printing. Quikrete LLC is the largest maker of packaged concrete and cement mixes in North America.

ORNL isn't alone in developing technology for 3D-printed buildings. The US Army Engineer Research and Development Center, NASA's Marshall Space Flight Center, Kennedy Space Center, and Caterpillar, Inc., collaborated to develop a 3D printing technology capable of printing custom-designed expeditionary structures on-demand in the field, using concrete sourced from locally available materials.

The Automated Construction of Expeditionary Structures (ACES) project provides the capability to print custom-designed expeditionary buildings and materials with minimum personnel, providing structures that improve the safety, security, and quality of life for forward-deployed troops and contractors.

The ACES program decreases construction time from five days to one day per structure while reducing the personnel required for construction from eight to three. The ACES program also reduces the resources and logistics associated with material shipment required to sustain the construction, including personnel. ACES construction would decrease the amount of material shipped from 5 tons to less than 2.5 tons. The ACES construction printer was designed so it can be loaded on a C-130 cargo transport aircraft.

Marines from the 1st Marine Logistics Group at Camp Pendleton, California, used the ACES 3D printer to successfully 3D print a concrete bridge. Marines learned how to operate the Automated Construction of Expeditionary Structures (ACES) printer, incorporating new equipment into the process, and printed and assembled a usable footbridge to demonstrate the concrete 3D construction printing capability in an operational environment.

The challenge for NASA is figuring out if materials on the surface of the Moon or on Mars can be used to make 3D construction cement for printing lunar and martian buildings.

Cement vs. Concrete Explainer

If you have cement and concrete confusion, here is a short explainer. Cement is an ingredient in concrete. To make concrete, a mixture of portland cement (10-15%) and water (15-20%) make a paste. This paste is mixed with aggregates (65-75%) such as sand and gravel or crushed stone. The cement and water mix harden and bind the aggregates into an impenetrable rock-like mass. Portland cement is the most common type of cement in general use worldwide as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin. Mr. Aspdin obtained the patent for Portland cement on October 21, 1824.

Concrete buildings will give the climate change constituency a heart attack. Concrete manufacturing is responsible for 8% of global greenhouse gas emissions. Manufacturing cement produces about 0.9 pounds of CO2 for every pound of cement. Cement is only a fraction of the constituents in concrete. Manufacturing a cubic yard of concrete (about 3900 pounds) emits about 400 pounds of CO2.

3D Printed Knuckles

This week, ORNL wasn't the only recipient of a taxpayer-funded additive manufacturing-focused patent. The University of Colorado received US Patent 11229533, "Prosthetic partial fingers." Their 3D printed partial fingers designs can mimic the last two joints of the finger, the knuckles. There are an estimated 500,000 amputees with partial hand amputations. The most common upper limb amputation is partial hand amputation with the loss of one or more fingers. This invention overcomes the limitation of static prosthetic fingers and cable-driven finger replacements. National Institute of Child Health and Human Development (NICHD) funded this research.

Get the Net — Another Drone Catcher

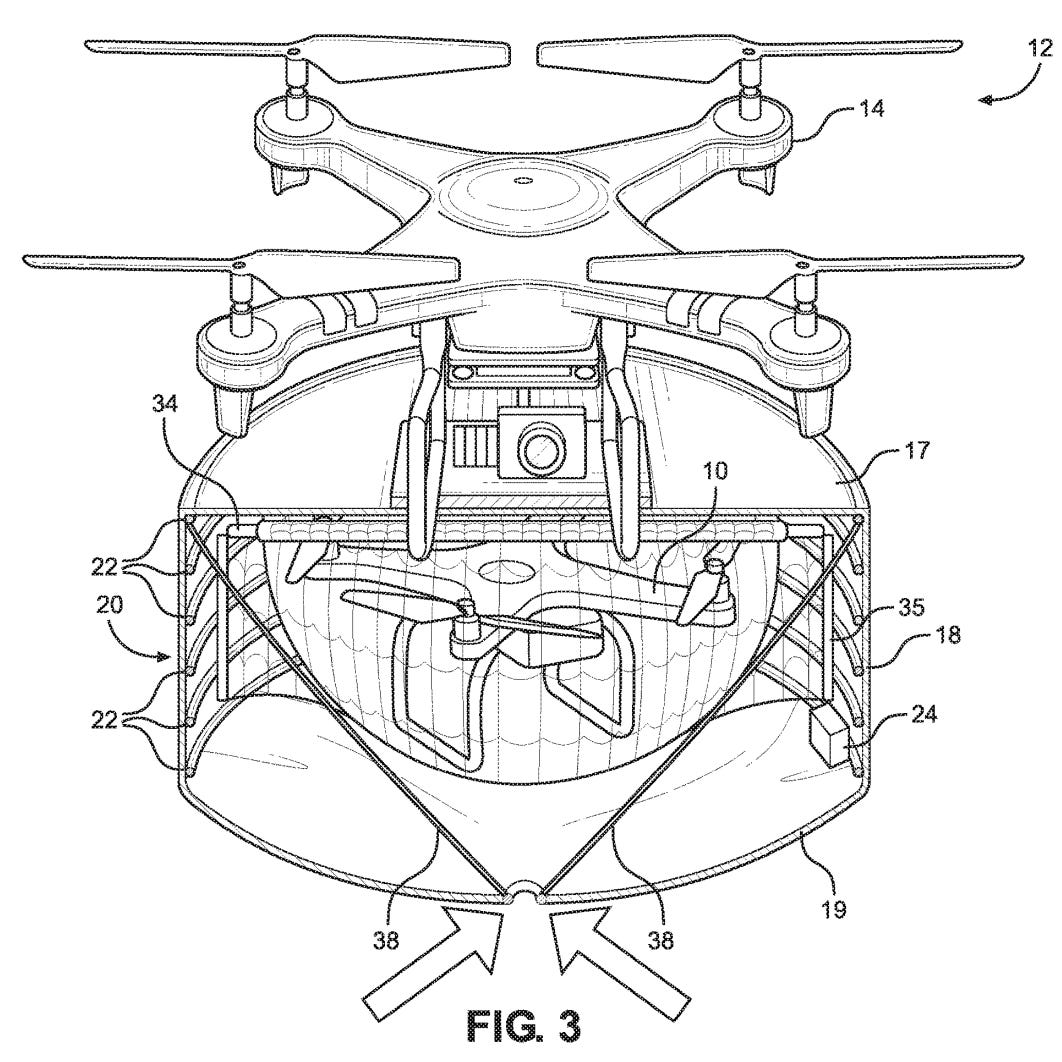

Defeating a "threat drone," an unmanned aerial vehicle (UAV) with a dangerous payload or being used for surveillance, is a national security priority at the Defense Department. The US Air Force Academy received US Patent 11231254, "System for physically defeating unmanned aerial vehicles." The friendly drone deploys a physical net on a rod that ensnarls the threat drone and then drags it back to where it can be destroyed or examined.

This patent is a companion to the Air Force Academy's 2021 patent, 11054224, "System for physically capturing and signal-defeating unmanned aerial vehicles," issued on July 6, 2021. You can read more about the patent in the July 7, 2021 FedInvent newsletter Drones and Shape-Shifting C-4.

Unmanned Lexicography

The patent includes the following definition:

"An unmanned aerial vehicle ("UAV"), commonly known as a drone, is an aircraft without a human pilot physically located within or on the aircraft."

Various spell checkers let us know that "unmanned" is a dated and non-inclusive term. Uncrewed, which the same spell checkers keep changing to "unscrewed," is the preferred alternative. The inventors called their drones Unmanned Aerial Vehicles, and since an inventor can be their own lexicographer, we're sticking with unmanned. (How is a human pilot can be physically located on the aircraft?)

Bayh-Dole Scofflaws — Raytheon Is Back!

This week, there are two Bayh-Dole scofflaws, companies that received taxpayer funding for R&D that led to their invention but didn't provide the statutorily required agency and contract information.

The FedInvent perennial favorite scofflaw is back. Raytheon Technologies Corporation received US Patent 11230940, "Controlled contact surface for a secondary seal in a non-contact seal assembly." This patent is for gas turbine engine and jet propulsion-related technology.

The second scofflaw this week is General Electric. GE received US Patent 11230972, "Refreshing heat management fluid in a turbomachine." This patent is also for gas turbine engine and jet propulsion-related technology.

FedInvent Patents By The Numbers

This week USPTO granted 5,744 new patents. One hundred thirteen (113) benefited from taxpayer funding. Here are the numbers.

One hundred eight (108) patents have Government Interest Statements.

Twenty-two (22) have an applicant or an assignee that is a government agency.

A federal department is the only assignee on seven (7) patents.

The 113 new patents have 131 department-level funding citations.

These patents are the work of 402 inventors.

The 387 American inventors come from 37 states, the District of Columbia and Guam.

The fifteen foreign inventors come from seven (7) countries, including three inventors from the People's Republic of China.

There are 76 patents (67%) where at least one assignee is a college or university, the HERD.

Six patents (6) resulted from the collaboration between two universities.

Federally Funded Research and Development Centers (FFRDCs) received ten (10) patents.

Nine (9) patents were assigned Y CPC symbols indicating that the invention may be useful in mitigating the impact of climate change.

The Big Three States — Win, Place, and Show:

The usual suspects are in the Win and Place positions. This week's patent Show position goes to Florida.

California has 16 first-named inventors and 69 total inventors.

Massachusetts has 11 first-named inventors and 37 total inventors.

Florida has eight (8) first-named inventors and 17 total inventors.

Patent Count

Count By Technology Center

The Technology Centers where this week's 113 newly granted patents were examined are in the chart below.

The Health Complex Funding Citation Count This Week

The table below shows this week's count of the number of funding citations where the recipient cites the Department of Health and Human Services (HHS), the institutes at the National Institutes of Health, and other subagencies that are part of HHS, the Health Complex.

The Health Complex Funding Citation Count This Year

We added the year-to-date citation counts for patents with funding citations from the Health Complex. Here is this week's chart.

Before We Go

As usual, there are many more taxpayer-funded patents than we can cover here. Please explore the FedInvent Patent Report. It helps you get more out of your newsletter subscription.

If you'd like to catch up on earlier FedInvent Reports, you can access the newsletters here on Substack. In addition, the reports are available on the FedInvent Links page.

If you aren't a paid subscriber yet, please consider subscribing. It will help us keep going in 2022. If you have colleagues or know patentistas who would enjoy reading FedInvent, please pass the newsletter along.

As always, we thank you for reading FedInvent.

The FedInvent Team

FedInvent tells the stories of inventors, investigators, and innovators. Wayfinder Digital's FedInvent Project follows the federal innovation ecosphere, taxpayer money, and the inventions it pays for. FedInvent is a work in progress. Please reach out if you have questions or suggestions. You can reach us at info@wayfinder.digital.